Brass vs. Aluminium: The Ultimate Durability Guide for Luxury Interiors

Introduction: Engineering Timeless Interiors

In high-end furniture and architectural elements, material durability dictates longevity. Brass and aluminium dominate premium designs – but their performance diverges dramatically in corrosion resistance, structural integrity, and aesthetic evolution. At TONA Interior, we deploy both metals strategically across our collections. This guide reveals when to choose each for Lahore’s climate and beyond.

Material Science Face-Off

Corrosion Resistance

| Factor | Brass | Aluminium |

|---|---|---|

| Humidity | Develops patina (protective layer) | Forms oxide barrier (self-healing) |

| Salt Air | Vulnerable to dezincification | Excellent coastal performance |

| Chemicals | Tarnishes with acids/ammonia | Resists household cleaners |

| TONA Verdict | ❌ Lahore monsoon risk | ✅ Ideal for coastal/urban projects |

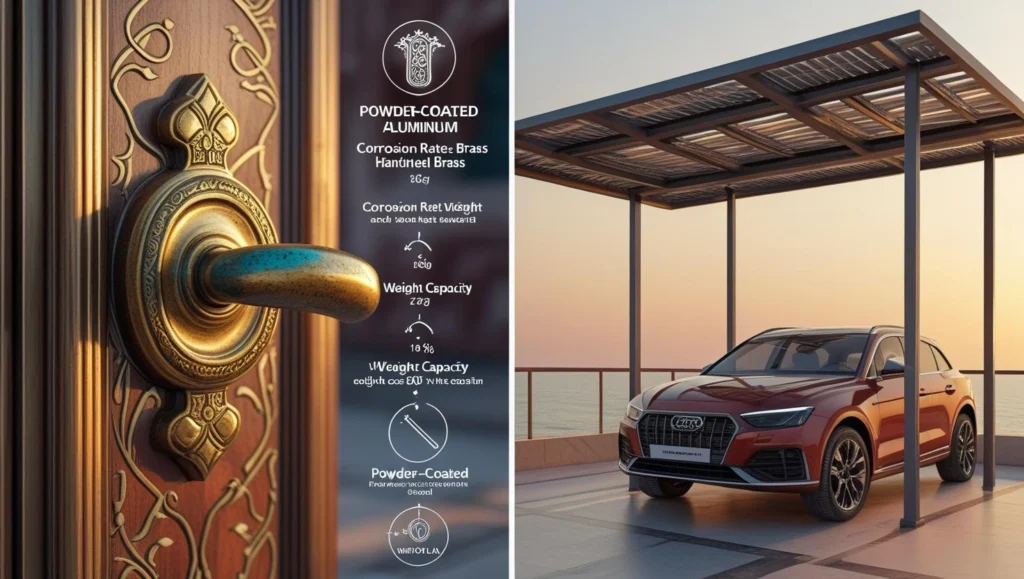

Structural Longevity

| Metric | Brass | Aluminium |

|---|---|---|

| Yield Strength | 125 MPa (medium) | 275 MPa (high) |

| Fatigue Limit | 50 MPa (low) | 95 MPa (excellent) |

| Weight Capacity | 800 kg/m² | 2200 kg/m² |

| TONA Use Cases | Decorative handles, accents | Car shade frames, ceiling systems |

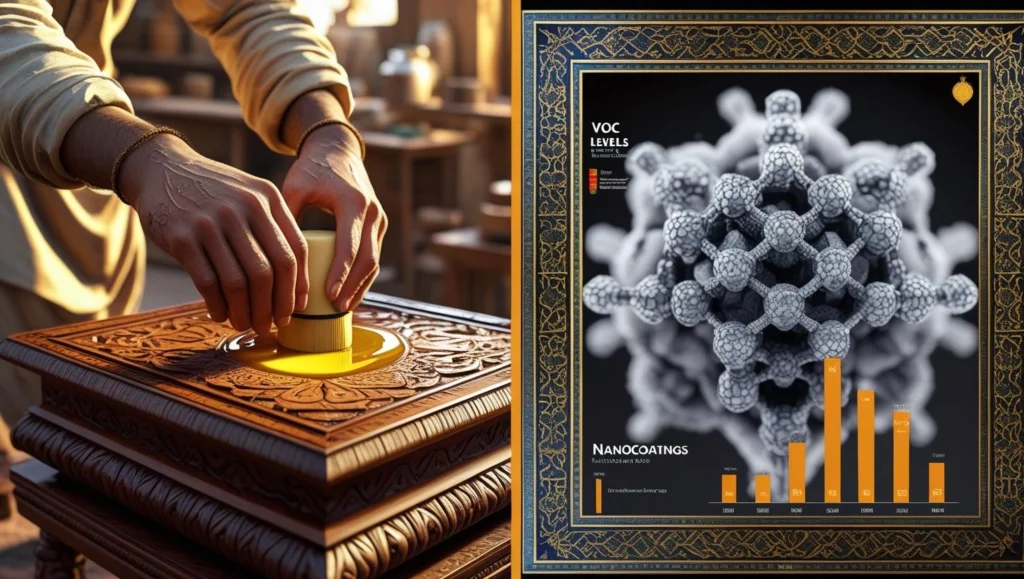

Aesthetic Evolution

- Brass:

- Process: Shiny gold → warm amber → vintage charcoal (5-8 years)

- Maintenance: Wax sealing required quarterly

- TONA Tip: Accelerate patina with vinegar mist for Mughal-era elegance

- Aluminium:

- Process: Maintains factory finish for 15+ years

- Maintenance: Annual soap wash

- TONA Tip: Anodize in Islamic patterns for permanent etchings

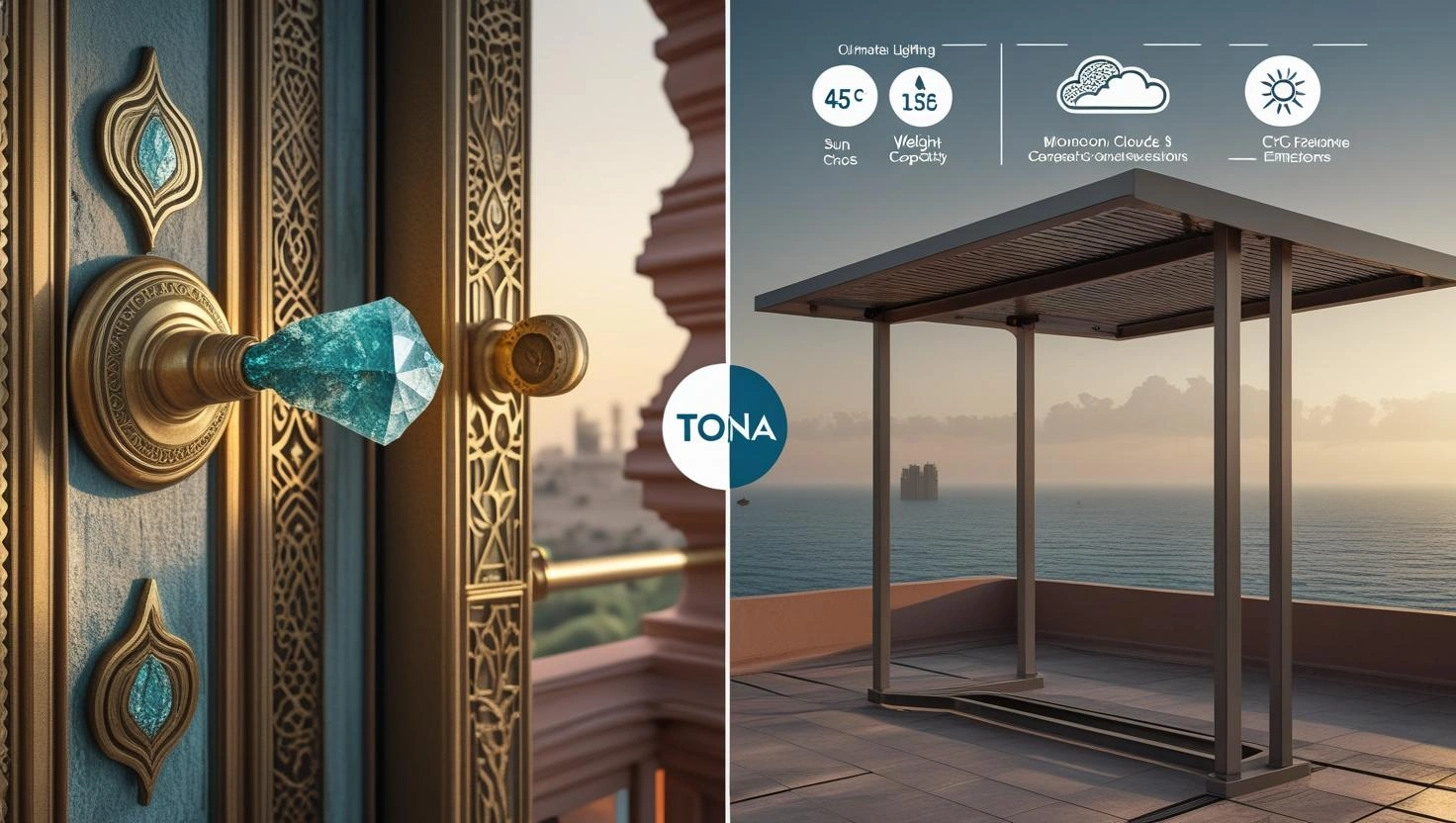

Climate-Specific Performance

| Condition | Brass | Aluminium |

|---|---|---|

| Lahore Heat (45°C+) | Expands 0.018% | Expands 0.012% |

| Monsoon Humidity | Patina accelerates | No oxidation risk |

| Urban Pollution | Sulfur tarnishing | Self-cleaning oxide layer |

| Winner | ❌ 2/3 conditions | ✅ 3/3 conditions |

Cost Analysis

| Factor | Brass | Aluminium |

|---|---|---|

| Material Cost | ₹8,500/kg | ₹2,200/kg |

| Fabrication | Hand-worked (high labor) | CNC precision (low labor) |

| Lifespan | 30+ years (with upkeep) | 50+ years (minimal care) |

| ROI Conclusion | Higher initial + maintenance cost | 62% lower lifecycle cost |

TONA’s Application Guide

markdown

- CHOOSE BRASS WHEN:

- Creating heritage pieces (Mughal-inspired door handles)

- Designing statement lighting (patina adds character)

- Budget allows artisanal maintenance

- CHOOSE ALUMINIUM WHEN:

- Structural integrity is critical (car shade frames)

- Low-maintenance requirements (high-rise balcony rails)

- Coastal/humid environments (LCD wall housings)

Sustainability Comparison

| Metric | Brass | Aluminium |

|---|---|---|

| Recyclability | 90% reusable | Infinite recyclability |

| Carbon Footprint | 8.5 kg CO2/kg | 6.1 kg CO2/kg (post-recycle) |

| TONA Practice | Salvaged colonial-era brass | Solar-powered production |